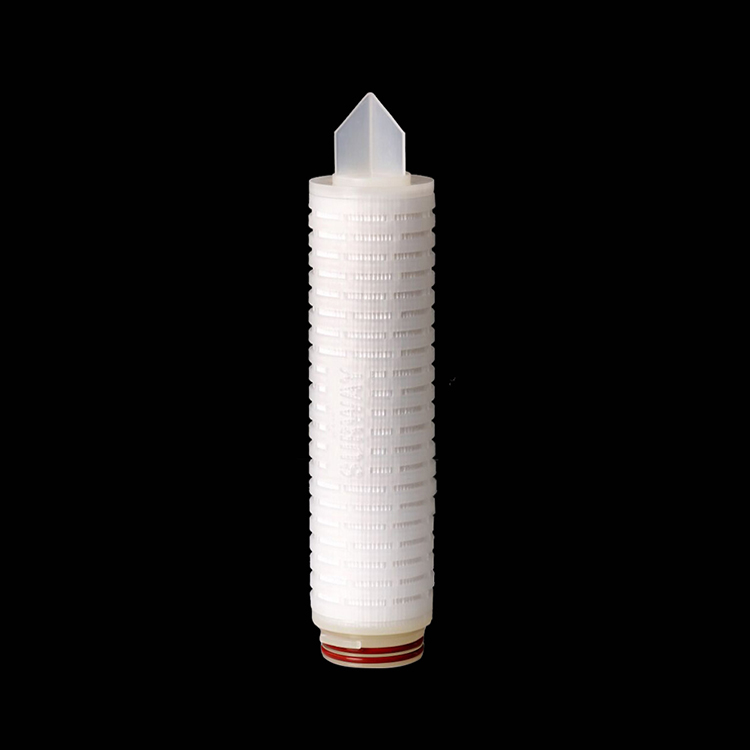

TECHNICAL SPECIFICATION

Dimension |

ø69mm | ø83mm | ø131mm |

Filtration Area |

0.6m²/10″ | 1.45m²/10″ | 2.3m²/10″ |

Length |

10″, 20″, 30″, 40″ | ||

The material of constructions |

Filer media: Nylon66,PTFE, PTFE/L, PVDF/L, PES, PVDF/B, GF,PP | ||

| Support Layer: PP | |||

| Cage/End cap: PP | |||

| Core:PP, SS | |||

| Sealing: S=Silicone, E=EPDM, B=NBR, T=Teflon, V=Viton, E=FKM | |||

Connection type |

F=DOE, H=213/Flat, J=222/Flat/ss, K=222/Fin/ss, M=222/Flat, P=222/Fin, Q=226/Fin, T=226/Flat, R=226/Fin/ss, V=226/Flat/ss, | ||

Operation conditions |

[Max. Operating Temperature]: 80℃ [Max. Operating DP]:4 bar@ 21℃,2.4 bar @80℃. |

||

Selection Guider |

Application |

| Nylon66 Series filter cartridge is constructed of nylon66 media and nonwoven support materials. The adaptors are thermally welded without the use of glues or adhesive to prevent any possibility of pollution. The filters are produced in clean room and 100% integrity tested and flushed with ultrapure water |

1. Wine, beer, mineral water, pure water filtration. 2. Solvents filtration 3. Fine chemical 4. Ultrapure water 5. Digital inks |

| Hydrophobic PTFE Series filter cartridge is constructed of hydrophobic PTFE membrane which has excellent chemical compatibility and corrosion resistance. This filter cartridge is suitable for the filtration to liquids and gases with strongly aggressive and oxidative. |

1. Compressed air, CO2Line Sterile filtration 2. Tank Vent 3. Aggressive acids, bases, solvents |

| Hydrophilic PTFE Series filter cartridge is constructed of hydrophilic PTFE membrane which has excellent chemical compatibility and corrosion resistance.The membrane is hydrophilic which can filter the liquid directly without pre=wetting to save the operation time. |

1. Mineral water, purified water, ozone, strong, oxidizing liquid filtration 2. High temperature liquids filtration 3. Strong alkali, acids, corrosive liquids filtration |

| Hydrophilic PVDF Series filter cartridge is constructed of hydrophilic PVDF microporous membrane with excellent resistance to high temperature and corrosion resistance, no fiber shedding. Filter media has good hydrophilicity, no need to do a pre=wetting treatment before filing water solutions. |

1. Oil & Chemical 2. Ophthalmics, WFI 3. Tissue Culture Media and Media a additives 4. Strong Alkaline, acids solvents |

| PES Series cartridge filter is constructed of imported hydrophilic asymmetric PES membrane and imported non=woven fabrics and silk netting as support and then pleated. The cage, PP core and end cap are thermally welded with media without using any glue. All cartridges are manufactured and assembled in a cleanroom environment. 100% of the cartridges are integrity tested and flushed with EDI pure water. It is suitable for filtering weak acid/alkali based liquid and ultra=pure water. |

1. Mineral water, Wine, beer and other Beverages. 2. Ultrapure Water 3. Chemicals 4. API, LPV, blood serum, biological, Buffers and other pharmaceuticals |

|

PP pleated filter cartridge is constructed of high-performance polypropylene filter media that got technological breakthrough type sub-micro level. The pores of the material are uniformly distributed. The construction is designed scientifically which makes the filter cartridge got a high flow rate. This allows users can filter the particles in liquid quickly and efficiently and save the cost.

|

1. Ink 2. Oil & Chemical 3. Plating 4. Semi-Conductor 5. Food&beverage 6. Industrial Water Treatment |

| MCE Pleated Filter cartridge is constructed of CN-CA Membrane filter media | |

| PFA Series filter cartridges are constructed of PTFE absolute=rated membrane, PTFE support netting, and ultra=pure PFA hardware. This presents a filter cartridge with excellent chemical compatibility, corrosion resistance, and low extractions to ensure high=efficiency filtration and long service life with chemicals. |

1.Machinery&Equipment

|

Glass Fiber series |

|

| Big pleated filter cartridge is designed for the filtration of the manufacture wetting process in the flat panel display. It has a larger filtration area and a higher flow rate. 83 series can meet the 5=6 grade line which has a requirement of 120 L/min flow rate, 131 series can meet the 7=10 grade line which has requirement of 250 L/Min flow rate. |

1.Industrial Water 2.Treatment 3.D. I. Water 4.Acids 5.Semiconductor |

ORDER INFORMATION

For example “CPNY010Q10SP”

Nylon Cartridge Filter, OD 69mm, Length 10”, 0.1um, 226/Fin, Silicone O-ring, pp core.

Series |

Filter Media |

Removal Rating |

End Cap Type |

Length |

Sealing Material |

Core |

| CP=69mm

CP1=83mm CP2=131mm |

NY=Nylon66 | 010=0.1μm | F=DOE | 5=5” | S | P=PP Core |

| PTB=PTFE | 022=0.22μm | H=213/Flat | 10=10” | E | S=SS Core | |

| PTL=PTFE/L | 045=0.45μm | J=222/Flat/SS | 20=20” | B | ||

| PVB=PVDF | 10=1.0μm | K=222/Fin/SS | 30=30” | V | ||

| PVL=PVDF/L | 30=3.0μm | M=222/Flat | 40=40” | T | ||

| PES=PES | 50=5.0μm | P=222/Fin | F | |||

| PP=PP | 100=10μm | Q=226/Fin | ||||

| GF=Glass Fiber | T=226/Flat | |||||

| PFA | R=226/Fin/SS | |||||

| V=226/Flat/SS |